Heads 1964 - 1990

Identification:

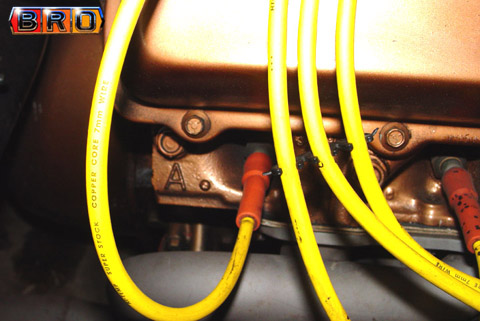

Scrape the grease off and read the letter at the lower

left corner of the head, near the #1 or #8 spark plug hole, it's about

1.5" high and indicates a big block, while a number indicates a small

block. Some have an additional letter (an A or B), about 1" high, right

next to the letter (or number). This is the quickest, easiest way to get

the most information about the engine.

Also, there is a 6-digit casting number, which might be among the rocker pedestals on early

or small block heads, but is generally found surrounding the center bottom rocker arm cover

bolt, 3 digits on each side, visible with the rocker arm cover in place.

To be absolutely sure, the last 3 digits of this 6-digit casting number are also repeated on the underside

of the head, near the intake ports. Don't pay $1000 for 'F' heads with the number '686' on the underside

( 'E' heads with part of the 'E' ground off )! Look closely for grinding marks, and globs of paint that try to

hide any alteration. The date code is the usual 1 to 3 digit numbers, about ¼" in height, in the exhaust

port area [??]. Looks like it was a plate screwed to the head mold - the screw heads are visible.

Generally, heads with valve rotators and corresponding deep spring pockets (3/8" wide

retainer rather than 1/8" retainer), have induction hardened exhaust seats from the factory.

Some heads are rumored to have the rotators on the intake or exhaust values only.

[ Thanks to Chris Witt for this information ]

Big Block Head ID/Codes, Casting Numbers, VIN Derivative Numbers

The 4 or 6 digit casting number is found around the center exhaust side rocker arm cover bolt or among the rockers on really early heads [pre-68]. Really late heads have #'s like 4417 or such, they might be out closer to the top of the exhaust port. This number is also found on each side of the lower middle valve cover bolt, split into 3-n-3 on each side of that bolt.

If it's an A, B, or C head, look for the engine unit number/ID code as detailed in the Blocks section under Big Block Unit Numbers. 1967 C heads had this number; 68-9's did not. So, if your C head has a stamped ID like V2023456G in figures about ¼" tall, that'd be from a 1967 400-4V, possibly a W-30. If no such ID is stamped in, then it's either a 68-69 C head, or a 1967 head from the left side of the engine. Check the other end of the other head.

ID/ Use Casting

Code Year(s) CID CCs Number Notes

A 65 400 80 383821 Unique 3/8" stud and nut rocker mounting, using a 3-piece rocker pivot assembly; all except irrigation.

425

B 65 400 80 383821 Later '65 heads. Some use 3-piece rocker pivot asssembly.

B 65 425

B 66 400 80 389395 Toro's and 442's got the big [2.072"] valves. Some use 3-piece rocker pivot asssembly. "-1" after the B 66 425  casting number asssembly. "-1" after the casting number on all B heads after April 21, 1966.

casting number asssembly. "-1" after the casting number on all B heads after April 21, 1966.

C 67-69 425 80 394548 A/C '68 H/O's. Toro's and 442's got big valves. Rumored to flow the best of all BB heads. Can still be

455

455

found.

found.

455

CA Very small ~3/8" ID lettering.

D* 68-69 400 69.75 400370 All W-30. Non A/C '68 H/O's. All '69 H/O's All big-valve.

455 69.75 400370

DA

E 68-'70 455 77,80 403686 455's in general, with 442/Toro's having big valves.

F* '70 455 80 404438 W-30's. All big-valve units.

G 71 455 80 409100 Generic 455 use, big valves in the usual applications.

Ga 72 455 80 409100 W-30's, manual 442's used big valves.

H* 71 455 80 409160 W-30's. Big Valve units.

J 73-'76 455 80,82 411783 All 445's. 'Smog heads', restrictive exhaust valve pockets. No big valve units.

K** 455 80 413191

Ka** 73-'76 455 80 413191 Marine, irrigation, industrial, W-30/Toro, 442 4-speed replacement head. Most were big valve units.

Notes:

* These W-30 heads are so rare that they command about $4,000.00/pair. Affordable for accurate restoration.

** While not quite as rare as the other heads, they are generally big valve units.

[ Thanks to Chris Witt, Daren, Joe Padavano, Jim Chermack for this information ]

Small Block Head ID/Codes, Casting Numbers, VIN Derivative Numbers

The 4 or 6 digit casting number is found around the center exhaust side rocker arm cover bolt or among the rockers on really early heads [pre-68]. Really late heads have #'s like 4417 or such, they might be out closer to the top of the exhaust port. This number is also found on each side of the lower middle valve cover bolt, split into 3-n-3 on each side of that bolt.

If it's an 1, 2, 3, or 4 head, look for the engine unit number/ID code as detailed in the Blocks section under Small Block Unit Numbers. If no such ID is stamped in, then it's either an 1968 and later head, or a 1967 head from the left side of the engine. Check the other end of the other head.

ID/ Use Casting

Code Year(s) CID CCs Number Notes

1 64 330 385101 Used ROCKER SHAFTS rather than pairs on PEDESTALS.

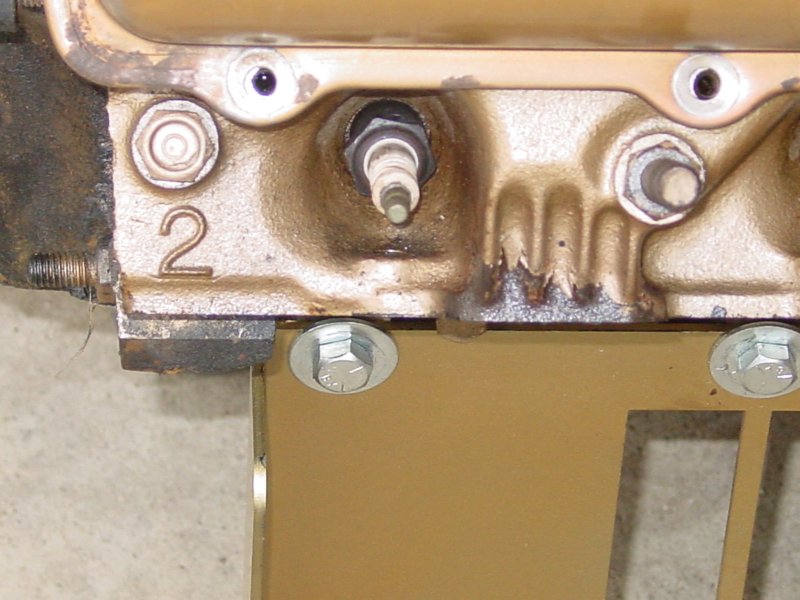

2 65 330 ?????? All V-8s now using PEDESTALS.

3 66 330 60 389394

4 67 330 60 394497

5 68-69 350 64 397742 Excellent candidate for use today. Good flowing, and high compression.

6 70 350 64 403859 W-31's had larger 2.000 intakes. '69 W-31's?

7 71 350 64 409147 W-31's had larger [2.000] valves.

7A 72 350 64 409147 The 'A' is a subscript, like ¼" tall, to lower right of the '7', like | 7A.

8 73-'76 350 79 411929 Smog heads. Have huge bb-sized 79cc chambers yielding poor compression ratios without extremes

of compensation.

of compensation.

10 76-'77? 260? 57 550362

2A 76-81 260 554715 Easy way to ID a 260 engine.

3A 77-80 350 75 554716 1/2" bolt holes.

4A 77-'79 403 83 554717 Matches the 4A or 4B block, get it? Easy way to ID a 403. 1/2" bolt holes.

5A 80-84 307 64 3317

85 also???

6A 85-?? 307 67 5844 Non-ECM Canadian cars?

7A 85-90 307 67 0142 This 'A', and the others from 2A to 6A, is a large capital letter equal in size to, and immediately adjacent

to the 7, like | 7A.

D3A 350 3948 Diesel.

From what I've seen, it appears that in '71 (when they needed to drop all of the compressions in GM cars - 10.5 to 8.5) that their first method of doing it was to dish the pistons more. In 1973 they increased the chamber sizes on the heads and went back to piston comparable to 1970 and prior.

[ Thanks to Brent Fields for this information.

Details

The 4 or 6 digit casting number is found around the center exhaust side rocker arm cover bolt or among the rockers on really early heads [pre-68]. Really late heads have #'s like 4417 or such, they might be out closer to the top of the exhaust port. This number is also found on each side of the lower middle valve cover bolt, split into 3 on each side of that bolt.

Be aware that most heads made before 1968 use a pushrod hole that corresponds to a 45& 39 degree; cam bank angle. What this means is the pushrods will rub the sides of the holes if the heads are used on a block with a 39&#degree; cam bank angle. All blocks 1968 and after use the 39&#degree; cam bank angle. Check the Cam Bank Angle, Lifter Size Considerations section for more information.

ID Casting # Combustion Camber Intake Valve Exhaust Valve

A 383821 80cc 2.000" 1.625"

1965 400/425 motor. Shallow spring seats. No hard exhaust seats. Unique 3/8" stud and nut rocker mounting, using a 3-piece rocker pivot assembly - may present difficulties in rebuilding or finding parts for the rocker assemblies. There is also another "A" head that has adjustable rockers, and look like Chevy heads that have screw-in studs. There is a single machined flat surface for each pair of stud holes. There are no rockers or pivots. Correct for 1965 442, etc. RH head will have the engine ID code stamped into the front. Some heads might have a B following the casting number, eg 383821B.

Applications:

B 389395 80cc 2.000, 2.072" 1.625"

1966 400/425's. Toronado and 442 heads had the larger 2.072" intake valves. Shallow spring seats. No hard exhaust seats. RH head will have the engine ID stamped into the front. First to use the one piece aluminum rocker pivots with 5/16" mounting bolts. Some early ones used the 3 piece rocker arm pivots with studs.

The big valve "B" heads with the -1 casting number are somewhat unique. As of 22 Apr 66 the head castings wore the -1 after the number. Looking at the build time of the 66 W-30 cars being June of 66 the later date codes on the heads would be correct for these cars. I've been told that this was a running change or update for the heads.

Jim Stohlman gave me the correct skinny on these. The L-69 (Tri-carb) cars were available in late December 1965. Therefore these cars should have regular "B" heads. Not -1's. The W-30's will ALL have -1 heads due to their late build date. ALL 66 W-30's were build on the Lansing line in one production run. Build dates of these cars should be around 6180 (meaning 1966, 180th day) or so. Therefore, all of them will wear the -1 heads. So did all the other cars that year.

The heads I've got are date coded for the 137th and the 138th day of 1966. Meaning these were in the window of the 90 days prior to all the 66 W-30's being nuilt. What I'm getting at is that the later the date codes the better they are for the W-30's. So far one of the latest date codes on a -1 "B" head is around 6150. There could be later, but this is the latest we've noted. Remember that for most restorations the acceptable dates for parts being installed on the car is a MAX of 90 days prior to the build date of the car. Anything farther out than that would require extensive documentation.

C 394548 80cc 2.000, 2.072" 1.625"

67-69 400/425/455's [except W-30 and most Hurst/Olds], including 1968 H/O with A/C. Valves commonly 2.000" and 1.625", but Toronado and 442 [except Turnpike Cruiser] heads had the larger 2.072" intakes. Presumably the H/O with C heads also had the large valves. Shallow spring seats. No hard exhaust seats. On 1967 engines, RH head will have the engine ID stamped into the front. Correct for 67-69 442's, even 68 H/O with air. Heads for 1967 W-30 or California cars had the A.I.R. passages [that boss on the exhaust port] drilled, tapped, and plugged. Some '68-9 442's with auto trans may have had small valves. This is reputed to be the best-flowing head, and is still fairly easy to find.

Our local head porting guru and engine buiding maven ("trained" by Mondello) both say that the only real difference between "B" and "C" heads is the size of the pushrod hole. Starting in 1967 there was more than one lifter angle necessitating a pushrod hole large enough to accomodate both. I have examples of both in my collection and this appears to be right. Small holes in the "A" and "B" heads. Drill out the holes in a "B" head and it will fit anything the "C" will. Don't and you may eat pushrods.

CA ?? ?? ?? ??

Both ID letters are quite small, about 3/8", with the C being just a bit larger than the A. Not sure of casting number, combustion chamber, port and valve sizes maybe the same as C's?

*D 400370 69.75cc 2.072" 1.625"

68-69 400/455's, with W-30 or H/O [except A/C '68 H/O's- see C]. Large valves, 2.072 and 1.625". Shallow spring seats. No hard exhaust seats. Smaller combustion chambers than other BB heads, possibly due to the small bore of the G-block 400 motors. Rumored that the '68 versions had both center exhaust ports connected to the crossover, whereas an improved later version as used in 1969 had one port blocked off from the intake heat crossover port for better power. "Improved port configuration for better flow"- according to Supercars Unltd. book 442 by the Numbers. Very rare and valuable.

*DA ?? ?? ?? ??

Not sure of casting number, combustion chamber, port and valve sizes maybe the same as D's?

E 403686 77, 80cc 2.000, 2.072" 1.625"

1970 455's, except W-30. Valves commonly 2.000 and 1.625", but Toronado and 442 heads had the larger 2.072" intakes. Valve rotators on all valves, therefore deep spring seats. Maybe have hardened exhaust seats.

*F 404438 80cc 2.072" 1.625"

1970 455's with W-30. Large valves, 2.072 and 1.625". Maybe have hardened exhaust seats. Valve rotators on all valves, therefore deep spring seats. One center exhaust port blocked off from the intake heat crossover port for better power. 'Improved port configuration for better flow"- according to Supercars Unltd. book 442 by the Numbers. Very rare and valuable. *THE* head to get, if cost is no object, or for an investment. Watch out for an E ground to look like an F; check the 6-digit casting number and the 3 digits on the underside as well (should not be 686). Always look for the two raised ribs on the end of the head that are nearly impossible to duplicate, even with JB weld. Only F heads had these ribs, never E's.

G 409100 80cc 2.000, 2.072" 1.625"

1971 455's, except W-30 [see H]. Valves commonly 2.000 and 1.625", but Toronado and 442 heads had the larger 2.072" intakes. Common heads use valve rotators on all valves, but 442 [and Toro?] heads used rotators on exhaust valves only- according to 442 by the Numbers. Wherever rotators are used, the thick rotator/retainer required the use of a deep spring seat. Maybe hard exhaust seats. The A is like 'A'. Some are large, some are small in size.

Ga 409100 [same number as G head] 80cc 2.000, 2.072" 1.625, 1.685"

1972 455's, including W-30. Valves almost universally 2.000 and 1.625", even 442's had small intakes, if auto trans models. Even the Toronados were relegated to small intake valves this year. Only 442's with W-30 or MT had the larger 2.072" intakes. No way to tell valve size without measuring a valve. Strange combinations of exhaust valve sizes and angles, depending on application. Weird combination of valve sizes and seat angles that no other heads matched. This might make finding valves more fun, should you need them. Exhaust valve with a unique 1.685" diameter and 30 degree face. All Ga heads use valve rotators on all valves, therefore have all deep spring seats. Hard exhaust seats.

*H 409160 80cc 2.072" 1.625"

1971 455's with W-30. Large valves, 2.072 and 1.625". Valve rotators on all valves, therefore deep spring seats. Maybe have hardened exhaust seats. One center exhaust port blocked off from the intake heat crossover port for better power. 'Improved port configuration for better flow"- according to Supercars Unltd. book 442 by the Numbers. Improved *over what* they don't say. Very rare and valuable.

J 411783 80, 82cc 2.000" 1.625"

1973-76 455 "smog" motors. Standard [small] valves: 2.000 and 1.625", even Toronado, 442, etc. [presumably]. Exhaust port is choked off to about 1" diameter just under the valve. No blocked heat crossover. Rotators, deep spring seats, hardened exhaust seats. Very common. Avoid.

*K, Ka 413191 80cc 2.072" 1.625"

1973-76 factory W-30/ Marine/ Irrigation head replacement unit. Rumored to have possibly been supplied as original equipment on some '72 W-30's. Accepted by the NHRA as a stock W-30 head. Large valves, 2.072 and 1.625". Big 80cc chambers which yields poor compression figures, but so are the C's, etc. unless you shave them. Rumored to flow not quite so well as C's [source: Mondello]. Valve rotators on all valves, therefore deep spring seats, allowing either rotator retainers or very stiff springs. Hardened exhaust seats. Exhaust heat crossover is NOT blocked off. Not quite so rare or expensive as the other 'exotics' (F, H's). Also said to be found in 1973-1974 standard shift big blocks found in Cutlass'.

ID Casting # Combustion Camber Intake Valve Exhaust Valve

1 385101

The rocker assembly is the same as later non-adjustables, except the aluminum cross pieces are stamped steel, and don't bottom out on the head. The pivots are individual and made of steel; they are linked together by the steel cross piece. These are adjustable rockers.

2

3 389394 60cc

4 394497 60cc 1.875 1.562

5 397742 64cc 1.875, 1.995 1.562, 1.624

All 1969 350s use the #5 head, 2bbl, 4bbl, or W-31, they all use it. The 2bbl and the 4bbl use exactly the same head. Same valves, springs, etc. Only the W-31 got the big valves and springs. Only W-31's were fitted with the larger valves.

6 403859 64cc 1.880, 1.995 1.567, 1.624

All 1970 350s use the #6 head, 2bbl, 4bbl, or W-31, they all use it. The 2bbl and the 4bbl use exactly the same head. Same valves, springs, etc. Only the W-31 got the big valves and springs and were filled with larger valves. Rotator style spring retainers were used on the intake and exhaust springs.

7 409147 64cc 1.880, 1.995 1.567, 1.624

All 1971 350's use #7 heads. Valve springs were different depending on application. Rotator style spring retainers were used on ONLY the exhaust springs. Induction hardened valve seats for use with unleaded fuel.

7A 409147 64cc 1.875 1.622

All 1972 350's use #7A heads. Valve springs were different depending on application. Rotator style spring retainers were used on the intake and exhaust springs.

8 411929 79cc 1.875 1.622

1973 - 1976 350 only. Rotator style spring retainers were used on the intake and exhaust springs.

10 550362 57cc 1.517 1.305

260 only. Rotator style spring retainers were used on the intake and exhaust springs.

2A 1.517 1.305

260 only. Rotator style spring retainers were used on the intake and exhaust springs.

3A 554716 75cc 1.880 1.507

1979 - 1980 350, possibly 1977 - 1980. Rotator style spring retainers were used on the intake and exhaust springs.

4A 554717 83cc 2.000 1.507

1977 - 79 403's only. This head's BB size chambers will reduce the CR (and power) of other SBs. Rotator style spring retainers were used on the intake and exhaust springs.

5A 3317 64cc

1981 - 1985 307. Used on the regular hydralic lifters engines. This head is preferred for 307 performance use because there are port matching problems between aftermarket intakes and exhaust headers with the 7A heads. 5a heads are rumored to flow slightly better. The 5a ports are larger than the 7A's, so this makes sense. So, if you switch from 7A to 5A heads you should get the intake and exhaust manifolds from the donor engine. Rotator style spring retainers were used on the intake and exhaust springs.

6A 5844 67cc

307. Possibly used only on non-ECM Canadian cars. AIR bosses, but not machined. Square ports, height equal to port width, which flows less than 5A heads. Rotator style spring retainers were used on the intake and exhaust springs.

7A 0142 67cc

1985 - 1990 307. Used on the newer hydraulic roller-lifter engine. Possible port matching problems with aftermarket intakes and exhaust headers. Square ports, height equal to port width, which flows less than 5A heads. Rotator style spring retainers were used on the intake and exhaust springs.

A 3948 1.875" 1.622"

The 350 Diesel used intake 1.875" and exhaust 1.622" in all applications. Flat combustion chambers for 22.5:1 compression! Get out your die grinder for custom heads!

Notes:

* - F,K,H,D... almost makes a word...

These are the 'exotic' rare, W-30/Marine/Irrigation heads, worth a bundle if you can find them. Usually indicates a W-30 engine or one that someone cared about a great deal. Wonderful things to have. Tough part is affording them, at about $1000 a pair, except for the K's, which are maybe half that. All are big valve units. May have been milled at the factory for smaller combustion chambers, therefore higher compression. D heads are rumored to come in 2 forms: with heat crossover blocked from one center exhaust port, and without this feature. The F and H heads also have blocked exhaust crossover passage, but K's do not.

Regarding CA, DA, Ga, and Ka heads, Olds apprently added this subscript when they made some sort of an internal change but kept the same basic casting number (witness the Fa 455 blocks, Ga heads, etc.). Unfortunately, I can't tell you what the difference is between the C and the Ca, for example, other than I would assume that the Ca was built towards the end of the 67-69 production span. Maybe these designate castings from a different foundry other than CMD (sort of like the PMD heads of later years)?

There has been a lot of talk that C heads are the BB head of choice. #5, 6, and 7 units are the best readily available units for small blocks. Of course, if you find a set of W-30 or W-31 heads for cheap, with the exhaust heat crossover blocked and all that. A set of D/F/H heads were recently commanding over $1000/pair, and needed rebuild at that. C's start to look real good, and you can still find those.

[ Thanks to Chris Witt, Brent Pinkstaff, Greg Rollin, Jim Chermack. Joe Padavano, Bob Handren, Thomas Martin for this information ]

Additional Details

260 Heads

The 260 heads have water jacket holes in between the intake ports. The orig. 2bbl intake covers them. I found this out using a mid 70's 4bbl intake (trying to make it perform at least a little!). When I filled the coolant back up, it kinda went everywhere. I swore a lot, and put the DualJet intake back on.

The moral of story? If you put 260 heads on anything (besides the garage floor) double check that all water ports are covered or plugged!

In my experience, the 260's girly-ports are matched by the later 307. Both have external port shapes that are rounded, whereas others have a squared external port shape. So, the 260 heads should "work", if you can call it that, on a 307.

[ Thanks to Charley Buehner, Chris Witt for this information ]

AIR or EGR Bumps

Can these heads be modified to run without the smog fittings? Does anybody have any experience with these heads?

OK, about those bumps... I've heard them called both AIR and EGR bumps, and both designations are kind of correct.

They are AIR bumps, because they serve as the continuation of the AIR boss to the inside of the exhaust port. If you're not running an AIR system, you don't need them.

The bump is simply additional cast iron designed into the head casting to provide enough material for the factory to machine in the provisions for the A.I.R. tubes on applications which required it. Apparently Olds decided that it was easier to use the same casting for A.I.R. and non-A.I.R. alike.

They are EGR bumps, however, since part of their (intended or unintended) function is to cause a restriction in the exhaust port, resulting in some of the exhaust mixture remaining in the combustion chamber, providing an EGR effect (though the gasses are not technically circulating.

Good point, however I must think that this is strictly an unintended function in the "it's not a bug, it's a feature" vein, as the bump existed as early as 1966, long before EGR was even conceived. Clearly the actual intent of the bump is to provide a location into which the attach feature for the A.I.R. tubes could be machined. Since it was easier to maintain one casting design instead of two, the bump was used on all heads, whether or not A.I.R. was used.

The A.I.R. requirement was CA-only in 66-67, then went away for a long time on Oldsmobiles, back in 1980. California heads were drilled and tapped for the air injectors. One easy way to prove that your 1966-67 is an original CA car. Instead of a separate casting for the rest of the world, Olds cast all the heads with the bump.

Those holes should be a NPT fitting, so any pipe-thread plugs that size should replace the connections. Again, save that emissions setup, in case you sell it and the buyer wants to restore it to its original state. I'd hate to imagine how hard it will be to find an original smog setup for a car like this.

I have used brass plugs for this & they are easily fitted, seal excellently, & are easily removed at a later date. This car should be ideal for today's fuel. Low compression w/a 4 barrel - perfect.

If the smog fitting (eg. air injectors) are still there, just remove the injector manifold. Then remove the injector tube from the exhaust port. This can be done by inserting something like a small screwdrive into the tube, then twisting and remove the tube. After that, just get some plugs and plug the holes. I ran a set of heads like this for years without any problems.

I ground the bumps off my #5 heads and it was a long job. They sure seemed harder than normal cast iron. Olds specific engine gurus claim a 15-25 hp gain by grinding the bumps away.

[ Thanks to Eric Brubakken, Bill Culp, Bob Barry, Joe Padavano, Mick Gillespie for this information ]

BB, SB Head Flow

It has also been said that all Olds BB or SB heads as a group will flow within 5% of each other. Unless you are turning over 6500 rpm, your heads probably won't be the limiting factor.

Best Flowing BB Head

The '67-69 C (#394548) heads are reputed to flow the best. Pretty much goes without saying that big-valve heads ought to flow better than comparable units with smaller valves. Bigger valves may diminish low-rpm performance and throttle response.

All Olds big block heads have the same mounting holes, port sizes, etc., and thus are interchangeable. Even the combustion chambers are equal at 80cc, plus or minus a little. Olds achieved different compression ratios by using pistons with different size dishes in the top. Some W-30 heads were rumored to have been factory-milled for a smaller combustion chamber. When in doubt, measure (CC the head).

Best Flowing SB Head

Dick Miller claims that #5 heads flow the best bone stock and untouched.

[ Thanks to Chris Witt, Mark Prince, Chris Urban, Bob Barry for this information ]

Exhaust Crossover Passage

Some W-30 heads have only one center exhaust port open to the intake manifold heat crossover. This is called "blocked heat crossover." If you can stick your finger from the intake heat crossover passage into both valve pocket areas of the center exhaust ports, it's not blocked; if your finger can access only ONE exhaust valve, that is blocked. Blocked is better, for performance. For similar performance gains, more mundane heads can have this crossover blocked with molten metal, etc., or a stainless steel shim can be placed over that heat passage when the intake manifold is installed.

Gasket Thickness

Today's thicker head gaskets [0.045" vs. 0.025"] place the head about 0.020" farther from the cam, which lowers the compression about ¼ point and takes that much out of the lifter plunger preload. If you have an engine apart, have the heads milled for the combustion chamber volume that your calculations indicate for the desired compression ratio.

Guides

In the case of most Olds heads, the guides feature a spiral cut inside the guide from the factory to aid in stem/guide lubrication. Which provides less material for the knurl to "expand". The bottom line that applies here is that old saying of "Save Money By Doing It Right The First Time".

[ Thanks to Greg Rollin for this information. ]

Hardended Valve Seats

Before 1971, all Oldsmobile street engines require lead. An engine uses lead for valve seat protection and octane boosting. GM states in the 1971 Owner's Manuals that all 1971 GM engines can safely use unleaded fuel. You might want to consider that 100,000 miles on an unopened engine wasn't a common occurance back then.

The lead (actually tetraethyl), when burnt in the combustion process is deposited on the valve seat. This cushions the softer metal of the pre 1971 heads. Without the lead the harder valve slams into the unprotected seat and will cause seat recession. This leads to burnt valves. Heads with soft seats are A - F. Heads with hard seats are G - K. Although some Ks might have the soft seats. I'll have to defer on 350 heads.

While I don't have a GM reference, I do have period magazine articles which refer to the low-lead requirement. It was a federal mandate in 1971 that all cars be able to run on low lead. This is the reason for the across the board compression drop from 10:1 or more to an average of 8.5:1. This compression drop resulted in a real horsepower drop (as opposed to the simultaneous apparent drop when net HP was used vs gross) and, of course, signaled the end of the muscle car era.

To distinguish the hardened valve seat heads from the earlier, non-hardened seat heads, Olds cast a small capital-letter "A" along with the larger casting number/letter. This letter is smaller, and down to the right from the main casting number/letter; hence, it is designated by the lower-case "a", even though it is cast as a capital "A" (also to distinguish it from the later 307's #7A head, where the capital A is the same size as the 7).

Heads with the small "a" designation are guaranteed to be hardened seat heads. Such as Ca, Da, Ga and also Ka and J heads. The J is the exception due to being a smog head from 73-76. Other heads (such as E and F) are rumored to have hard seats, but only your budget, gut feelings, and eventually the heads will know for sure.

I guess since the "A" is more of a revision code, and not really part of the casting number/letter (unlike the 3A, 4A, 5A and 7A heads on the '77 and later cars), the '72 heads are called "#7" heads officially.

Studies made on pre-71 engines showed that unleaded gas normally would not be horrific to your engine unless you were at sustained high rpms, such as drag racing, or using 6.13 gears on the street or something similar. Theoretically, an engine running on no-lead will need a valve job sooner than one running leaded, even under normal driving. But no-one I know of, including myself, have ever run across this no-lead curse.

The lead in fuel helps soften the pounding of the valves against the seat. This is where you would find the damage. More so on the "hot" exhaust side. The valves have a tendency to sink into the head. Although most engines would be succeptible to this sort of wear, Olds heads usually don't suffer this type of wear very often. At least not to the degree some do. Chevies seem very prone to this valve sinking, however, based on the number of junkyard buildups I've read in the car mags.

Heads without hard seats will go about 60,000 miles on unleaded gas. In a car that will see a lot of driving, you will need the hardend seats installed. Valve recession is apparently not a big problem for street-driven cars. Though the lead is gone, there are additives in gasoline today that perform much of the same lubricating function. The only time you absolutely need hard seats are on an engine that is not going to be apart for a longer duration than that. All these shops that insist on hard seats do so because they sell/install them.

Almost any machine shop can install the hardened valve seats. This in conjunction with a 3 angle valve job. Also an octane boost will help. I have only found one octane boost that earns my seal of approval. It is called Lead Supreme 130. It will formulate today's pump gas into yesterday's Rocket fuel. Contact: Stone oil co. area code 912-489-2896. They will ship UPS. 1 ounce of this stuff per gal. can increase octane 2 points.

Use a fuel additive that contains lead if (1) your heads are pre 1971, (2) your compresion ratio exceeds 10.1, (3) you have no catylitic converters, and (4) you rev past 3 grand regularly.

The ~only~ time I have seen any damage to valve & seats were newer (1980's series) Chevrolet 350 engines, with the .375 diameter valve stem sodium filled exhaust valve, as opposed to the 11/32 (.312) std sized valve stems. I used to run into a bit of valve pitting and recessed seats on those "Heavy Duty" heads. Go figure out that engineering!!

A caution about having hardened seats installed. Make sure that they're of the right depth for Oldsmobile heads, as Chevy seats are too deep, and machining for that depth will end up in the water jacket.

[ Thanks to Joe Padavano, Mike Rothe, Steve Reed for this information. ]

Head Bolts

The head bolts on the lower #2 had the studs. On early cars 1964-67 they were used for A/C on the pass. side and power steering on the drivers side (alt was in the middle on A/C cars). 1968 and later were used for A/C on the pass side and Alt on the drivers side. Power steering was on the lower drivers side head.

Olds engines used 7/16" head bolts up 'til 1976, after that they used 1/2" head bolts. The 7/16" head bolts took 85 ft/lbs of torque, and the 1/2" bolts took 130 ft/lbs.

[ Thanks to Jim Chermack, Bob Barry for this information. ]

PMD Head Castings

Pontiac Motor Division (PMD) was commissioned, for lack of a better term, to produce Olds heads. The letters "PMD" will show up on the heads, rather than CFD. The heads are much lighter than the Olds-cast units, I believe they started showing up about the same time the blocks got the windowed main webs -- I don't know 100%, but I'd bet most of the 307's and some of the last 350's might have these heads on them. The sure-fire way to spot them is to look at the top of the exhaust runner on the head (area just below the rocker cover) -- the Olds-cast heads are rectangular and have distinct "ridges" in these areas, the Pontiac units have a rounded top and no ridges. I'm not sure if these are the only Olds heads that use only 5 bolts in the rocker cover or not, but I'd bet none of them came with 10 bolts per head.

While the Olds heads were built by Pontiac, they were no good. They didn't flow as good as the mediocre Olds-built ones (can't even compare them to 5's, 6's, or C's through F's, just compare them to the 260 heads!), the only advantage is they are lighter, much like the blocks of the era.

[ Thanks to Ken Snyder for this information. ]

Rocker Arm Covers (Valve Covers)

Regarding covers used on A-Body cars, you would be surprised to know they used quite a few different valve covers over the years. The 1964-65 are unique, 1966 was flat, 1967 was the first year for a notched on the drivers side only, then in 1968 they still used the flat ones for small blocks and the notched for big blocks. This was the same until 1972. In 1973 they went to the ones with Oldsmobile stamped into them, and they were no longer flat, but kind of shorter on the bottom near the plugs. Later they changed them again to only 5 bolts instead of ten and no Oldsmobile on them. Confusing Huh?

[ Thanks to Jim Chermack for this infomration. ]

Rocker Arm Ratio

All Olds heads use rockers with a 1.6:1 ratio. By a mathematical coincidence, this is also the ratio between movement at the rocker pedestal and the movement of the pushrod. That is, if there is 0.030" clearance under the rocker pedestal with zero valvetrain lash and zero lifter plunger depression, then there will be 0.048" [0.030*1.6] of lifter plunger preload when that rocker is tightened down.

Since the heads are very similar, and the 350 has a large 4.057" bore, you can put the 2.000" valves, and probably even the 2.072" intakes into a SB head, but it'd probably lose some low-end throttle response to gain some high end WOT power.

[ Thanks to Chris Witt, Tom Millard for this information ]

Valve Rotators / Spring Seats

Starting with the E/F heads in 1970 came valve rotators, which required deeper spring seats to be cut. With those heads, you can use valve rotators, or standard retainers and stiffer, longer reach springs suitable for very high lift cams [over 0.600" valve lift]. Shallow spring seats do not allow valve rotators or very high valve lift. Shallow seats can be cut deeper to suit, however. The presense of rotators doesn't necessarily indicate hard exhaust seats.

Valve Sizes

Generally speaking, there were two intake valve sizes: standard run of the mill engines used 2.000" valves [which also served as the small blocks' "big valve"], and performance engines used the larger 2.072" intakes. A small, but not negligible, 3.6% difference. Generally speaking, for heads up to and including G, the large valves have a 30 degree face, and the 2.000" valves have a 45 degree face. Almost all heads used 1.625" exhaust valves with a 45 degree face. Notable exception would be the 1972 Ga heads. Aftermarket performance exhaust valves are commonly larger than stock: 1.710" diameter. Any head can be fitted with larger valves, this only requires grinding the seats to match, about $50.

No, there is nothing externally to identify the heads as BV or SV units. You can tell, however, if you know what their original application was:

BV=442, W-32 (SX), W-33 (Delta) and W-34 (Toronado GT) motors

SV=all 2-bbl, all 98, L-31 (SX, Vista Cruiser and Delta 88-series), Toronado non-GT

Identifying Sizes

Four barrel carbed engines were not necessarily equipped with large valve heads when a two barrel carb could be configured. For example, I recently pulled a set of small valve (1.998") C heads from a '69 Delta 88 with a high compression 455 4 barrel. This motor had never been disassembled until I took it apart, so I am certain it came from the factory this way. (the original exhaust bolt clamps were still in place and it had the factory .025" metal head gaskets). Also, the book 4-4-2 by the Numbers states that "We have found small valve heads on many 1968-1969 4-4-2's with automatic transmissions".

Various valve lengths were used by the factory, with as little as 0.005" difference in length. Generally, the pre-'72 Toronado and 442 engines used the same valves, while more common engines had slightly different length valves of smaller head diameter. When a valve job is done, the valve tip is generally ground a bit, and the valve has moved due to cutting of the seat and face anyway, so what difference 0.005" might have once made is probably lost. The most important thing to check is that when you assemble the engine, you have the recommended 0.050" lifter plunger preload [+/- 0.020" or so].

Telling a big valve E head from a regular 2-incher is easy as long as nobody has done any head work to it. All big valve E heads have valve spring dampers in them and standard small valve heads do not. So all you have to do is to pop a valve cover off and peek at the valve springs. If you see wahat appears to be a flat spring inside of the regular valve spring it is a big valve head. If you just see a single valve spring with nothing else, then it is a small valve head. Keep in mind that this rule applies to 1970 E heads only.

All C heads have valve spring dampers so you will have to remove the head and measure unless it is a 2-barrel motor. then you will know that is a small valve unit.

Big valve Ga and the ultra rare big valve J (1973 M.T. cars only) also go by this damper rule.

1971 G heads for the most part do too, but some small valve units have dampers on springs without rotators.

Keep in mind that the big valve damper rule only applies to E, Ga, and J heads. All D, F, H, K and Ka heads were large valve and will have dampers too. All B, and most C heads will have dampers on both big and small valve units so a removal and measurements will be needed.

As far as small blocks go, I am more familiar with 330's. I have done work on many 350's and 307's but I am less vested in knowledge as I am in big blocks, but here goes!

W-31 motors were the only 2-inch small block heads, exept for the 200 HP 403's that were in 77 Toro's and I believe 77-78 Trans Ams?

1970 and 1972-up small blocks did not have dampers. In 1971, Olds did not run valve rotators on intake valves (Gotta check on this to be sure, could be exhaust) The springs without rotators got dampers on small blocks in 1971. Before 1970 I believe all small block heads had dampers.

Performance Modifications

It should also be noted that small valve heads can easily be machined to accept the big valves since both small valve heads and big valve heads came from the same casting.

Large valves can be installed in the small block heads or any heads in general. My number 5s were machined for 2.072" intake and 1.710' Ex. With this combo you can't put hardened seats in the heads, but with stainless steel valves you shouldn't need them. The largest ex. valves you can use with 2.072 int. and still put in the hardened seats is 1.68".

This brings up a good point regarding the difference in actual valve size, \ and any performance advantage. I realize that the bigger the valves, the more airflow typically you can get in the cylinder (disregarding any MAJOR differences, and looking at the basic type of intake tract). But how much is it really worth to have the larger valves? Is it worth extra HP, or is it not a valid need until higher RPM. My contention would be this. With a normal street motor, running typically at 3000 RPM, and occasionally up to say.... 5500-6000 range, I'd bet there isn't much of a difference in the basic overall view of things. It may be down a bit on HP when buzzing the redline a bit (with the big valves), but face it, how many people here spend any considerable amount of time at that RPM?

In fact, I'd say that for people that really like the "grunt" of the bottom end of these motors, you may be better off with the smaller valved heads (yep, you heard right...). Typically you will make better low end power with the smaller valves than with the bigger ones (the same thing can be said for carburetion also, in that a smaller size carb will give better low-end power, and a bigger carb tends to lose bottom power, but gain top end).

Is it worth "ditching" your small valve heads for a pair with a bigger valve (considering you're staying within the same year, and not comparing the smog heads to non-smog). I'd say no. Keep the ones you've got, and spend the money on getting them ported if you have money to blow. There's better things to spend the money on than this. There are alot of other things in your powertrain that will NEED to be worked on before you get into things this far to make a big difference.

[ Thanks to Brad Otto, Mick Gillespie, Robert Barry, Tony Waldner, Chris Ruper for this information. ]

Valve Spring Pockets

Many heads use rotators on the intake and exhaust valves. So yes they do have deeper spring seats than the earlier models with solid retainers. The deeper spring seat is required to compensate for the thicker rotator style retainer. The spring installed height for all (stock) big block heads is 1.670" regardless of the retainer style.

If Comp Cams calls for a taller installed height, you can use different (solid) retainers to make up the difference, rather than machining the spring seats. These should be available thru Comp Cams, if not they are from other brands. I would recommend using steel retainers over aluminum on a street application. As the spring dampers will tend to dig into the aluminum, thereby sending aluminum particles through the engine. When using aftermarket retainers, be sure to check for clearance between the rocker arm and retainer. This can be done on the bench. As with any cam, to optimize its potential, always use the manufactures recommended matching springs.

With .540" lift, be sure to check for adequate clearance between the retainer and valve guide (with whatever seals you are using installed). The guide may very well need to be shortened. If you are planning on using stock style rocker arms, make sure the slot is long enough for the amount of lift. The slot may need to be elongated with some of the "replacement" style arms on the market.

Be careful with aftermarket valve springs. Many heads use shallow spring seats. Many aftermarket springs are designed for the more common deeper seats, and won't install to the correct height with the springs you get with the kit. In fact it takes a lot of muscle to get them installed at all. The height will end up .090" too short. My machine shop almost sent me home with my heads set up like this until I checked the dimension myself. Even then they tried to tell me it wouldn't be a problem.

The best solution is to machine the spring seats .090" deeper to get the correct installed height and also the correct preload on the springs. I'm sure you would bend valves, pushrods etc. if you don't get them right. Another solution I guess would be to use longer than stock valves (Mondello sells them), but I'm not sure what other problems they would cause. With a 403, the spring seats should be at the depth that matches the Edelbrock package. I know they are for 350 heads, #6 and above.

[ Thanks to Greg Rollin, Mick Gillespie for this information. ]

Weight

Olds cylinder heads weigh 58 pounds each approximately.

[ Thanks to Gene Gatti for this information. ]

Intake, Exhaust Port Sizes

SB and BB intake ports are definitely different:

Big Block

Head Floor Roof Width Height

A

B

C 0.470" 2.85" 1.37" 2.37"

D

E

F

G 0.470" 2.85" 1.37" 2.37"

Ga

H

J

K

Ka

Small Block

Head Floor Roof Width Height

1

2

3

4

5 0.435" 2.45" 1.30" 2.03"

6

7

7a

8 0.435" 2.45" 1.30" 2.03"

10

2A

3A

4A

5A

6A

7A

Note: Floor was measured above the block/head surface for all heads.

These measurements were taken with a dial calipers, and there was some variation among ports, up to 1/16" = .060". Head overall height, width, and port position along the length of the head were very nearly the same for all heads.

The 5A heads have the 'std.' older larger regular SB size ports, not the miniscule nostrils that the 2A, 10, 6A, 7A heads have. Port size mismatch occurs with these heads and most factory and all aftermarket intake manifolds. Earlier SB's used rectangular ports, about 1.25 x 2". The 260 and later 307's, starting with the #6A heads, have teeny tiny ports, same width, but height cut down to about equal to width. So, imagine the A/F coming down the intake, all happy in its 2" tall port, when wham 1/3 of it has to STOP or cram into the rest of the space left by the port there in the head.

Starting in mid 1985, Olds switched to a different head (coded 6A and 7A). They, for some unknown reason, shrunk the size of the intake ports. The result was a reduction in horsepower by about 10 on the "Y" motor. The other consequence is the ports don't match the larger size on the Performer and other aftermarket manifolds, causing "reversion". In other words, the air/fuel flow bounces back into the manifold, creating backpressure and (probably) worse performance than the stock intake. I'm guessing, but Edelbrock and other performance parts makers most likely don't find it cost effective to produce a manifold for an engine/head combo produced for only three years (86-88).

So, the BB ports are about 3/8" taller, with the difference being at the top of the port. Bottom is virtually the same location. Mind you, the later model engines, like 260, 307, 350's with 3A or 5A heads, etc. may have very different ports.

[ Thanks to Chris Witt, Jeff Herndon for this information ]

Combustion Chambers, CC's, Interchange

Virtually all Olds big block heads have the same roughly 80 cc combustion chamber (with the exception of the 68-69 D heads). Olds varied compression ratio by changing the size of the dish in the piston, not the heads. This was also done with small block heads, although they changed from time to time to varying the combustion chamber size rather than the piston size.

Realize that most rebuilding information uses Oldsmobile's published 72cc combustion chamber blueprint spec. This is the number that you're allowed to go to for NHRA stock racing, so the piston manufacturers rate compression with this chamber number. Same goes for the thin head gasket; the OEM thickness is the one listed as the blueprint number. It's not the piston manufacturer's fault that most Olds heads run significantly over the 72cc number. Note that when I ordered the 10.5:1 pistons for my 455, the person taking the order specifically pointed out that the compression rating was with 72cc chambers. The piston manufacturers may actually do this as somewhat of a safety mechanism also, as I suspect the uninitiated engine builder may purchase higher compression pistons that he/she really should. Being able to brag that you have 10.5:1 and still being able to buy gas for the car has some benefits. Also, NHRA blueprint specs list the dish size and call that 10.5:1.

From the spreadsheet, we examine what becomes of the compression ratio of a SB Olds if we swap heads from some other SB Olds engine.

A large number of assumptions have been made in the above. Do NOT take this as gospel. First off, the heads' cc numbers are not from personal measurements - subject to typos, etc. Then, since I did not know the exact CRatio for all engines, like the #10 head 260, I assumed about 8.0 or 8.2:1 was a good start. Also assumed that the gasket volume did not change [not very realistic until after they started using the thick gaskets we see today].

With these assumptions, the method was:

CRatio == volume at BDC/ Vol at TDC, by definition.

CV == 'Clearance Volume' = all volume at TDC = head volume + gasket vol.

+ deck clearance vol. + piston dish vol, etc.

PSV == Piston Swept Volume = engine CID / # cylinders.

Vol. at BDC = CV + PSV

Thus, mathematically, CV = (PSV) / (CR-1.0) which gets us the total clearance volume listed in the 5th and 6th columns [ci and cc resp.]

New CV = Old CV - Old head's chamber size + new head's chamber size. EZ!

New CRatio = (PSV/ New CV) + 1.0

Heh, the SB only engine the #8 heads will give a CR over 8.0 is the 403!

Eng Head Head Stock *Cyl vol* New CRatio, w/ head of chamber size: [cc]

CID ID cc CR ci cc 57 60 64 67 75 79 83

330 3 60 9.0 5.16 84.5 9.29 9.00 8.64 8.39 7.79 7.53 7.29

330 4 60 9.0 5.16 84.5 9.29 9.00 8.64 8.39 7.79 7.53 7.29

350 5 64 9.0 5.47 89.6 9.68 9.37 9.00 8.74 8.13 7.85 7.60

350 6 64 9.0 5.47 89.6 9.68 9.37 9.00 8.74 8.13 7.85 7.60

350 7 64 8.2 6.08 99.6 8.74 8.50 8.20 7.99 7.48 7.26 7.05

350 7a 64 8.2 6.08 99.6 8.74 8.50 8.20 7.99 7.48 7.26 7.05

350 8 79 8.0 6.25 102.4 9.91 9.59 9.20 8.93 8.28 8.00 7.74

260 10 57 8.0 4.64 76.1 8.00 7.73 7.41 7.19 6.66 6.43 6.22

260 2A ?? 8.0 4.64 76.1 --can't do it w/o head cc info--

350 3A 75 8.0 6.25 102.4 9.49 9.20 8.84 8.59 8.00 7.74 7.49

403 4A 83 8.2 7.00 114.7 10.3 10.0 9.63 9.37 8.74 8.46 8.20

307 5A 67 8.2 5.33 87.3 9.13 8.83 8.46 8.20 7.60 7.33 7.09

307 7A 64 8.2 5.33 87.3 8.83 8.55 8.20 7.96 7.39 7.14 6.91

Interchange Head ID: 10 3-4 4-7 5A 3A 8 4A

Hoo-boy, look at that 260 with 403 heads... 6.22 compression ratio!

[ Thanks to Chris Witt, Joe Padavano for this information ]

Modifying and Tuning

Blocking Manifold Heat Crossover Passages

I advise against using stainless steel shims to block the manifold heat crossover passages. I used to use my just-removed intake "bathtub" as a source for clean stainless, since anything much thicker would affect the manifold sealing. This works well for an engine that is torn down frequently (once per year). Beyond that, the steel starts to deteriorate (gets warped and thins out). I had one of these plates break up and a dime size hole appeared when a piece broke off. Thankfully, the fragment that came loose slid downward and was trapped harmlessly between the shim and the manifold; could have been quite damaging if it had been ingested.

I saved up my pennies and put about a pound of Mondello's zinc aluminum alloy in each head. Best money I ever spent. I did this myself, with a handy lab furnace at work. You can use a small cast iron skillet to hold the alloy, and one hell of a good potholder to hold the skillet. Helpful hint: install two old (unwanted) exhaust valves in the center ports with springs to hold them tightly shut. I used an 18 inch piece of 2x4 and bolted over the exhaust crossover outlets (where the intake manifold usually is), countersinking the bolt heads to ensure the head would stand on edge in a stable (read SAFE) manner. Next, you should pour the molten metal (in the port outlet where the exhaust manifilod normally goes) at a good pace so that it hardens as one piece and not in layers. A few gentle raps with a rubber mallet, as you pour, by a second person will help displace any air bubbles.

On another set of heads, I did not use the exhaust valves, so I was only able to fill up the ports until the alloy ran out of the exhaust valve pockets. No harm was done to the valve seats. Because the alloy had a pretty high surface tension, I did not get optimal filling of the entire passage. The top of the alloy cooled in a dome shape which was not tightly in contact with the walls of the port.

While the passage was certainly completely blocked, there was not alot of alloy that projected into the port area for optimal porting of the long side of the runner. Of course, a completely blocked passage is bettter than no block at all, and I was able to shape the pockets pretty well with my trusty CP die grinder and assortment of carbide burrs. I recommend filling the passages right up over the valve stems. This will ensure that enought molten material will contact the walls of the passage for smooth porting. This should provide more than enough meat for port work. I would rather have too much since it ports out quickly with the die grinder.

The alloy seems like very durable stuff, but ports with the same ease as cast iron. To date, I have had no problems with durability. On a cool evening, in conjuction with the OAI hood, the car feels massive. After a good highway cruise, you can put your hand on the intake with no discomfort from heat! The car will take longer to warm up and may stumble a bit when you stop at the off ramp after a cruise on the highway. If you want smooth idle all the time, better buy a road turtle with EFI. For the boulevard cruiser, blocking off the passages won't provide as great of a benefit, since normal heat soak will eventually warm the manifold to the same temp as the rest of the engine. It's the passage of air and evaporation of the fuel (i.e. high speed cruising) that cools off the intake. I used to cruise the highways for a while, then get on the boulevard within a few miuntes. Rarely lost!

[ Thanks to Scott Mullen for this information ]

Head Gaskets

Today's aftermarket and replacement head gaskets, eg. Fel-Pro teflon, seal a whole lot better than the old solid steel shim gaskets, but I suspect that the result is a thicker package, which lowers the overall compression ratio a bit. Second, I think that most replacement gaskets for all motors are a little thicker than OEM for the 60s to provide a small drop in compression for today's lower octane gasoline.

[ Thanks to Joe Padavano for this information. ]

Head Porting

Please Note!! Do any head porting before you do the valve job; one nick of the valve seat (and if you work from that side of the port, you will nick the seat) and you've got to do it over anyway.

If you are really concerned with maximizing flow, just follow the standard porting techniques for Olds heads. Remove A.I.R. bump, teardrop the valve guide, port-match the intake and exhaust ports and manifolds.

High velocity ports and good low lift flow are what you want. Keeping the fuel in suspension and providing a strong signal to the carb help torque. Large valves with an unshrouded combustion chamber will help achieve this. Spend your money on the best valve job you can. Get all of your valves backcut. Put in larger valves if you can afford it (this is expensive). The valve and the valve bowl are the major flow resrictions in your head. Smothing rough machined edges in the valve bowl and removing the AIR bump in the exhaust port will give you more flow. Enlarging the port will not help. The port opening usually flows better than the valve seat and bowl anyway. Just smooth rough edges and keep material removal to a minimum.

I don't know about port matching, I have heard that as long as the intake manifold ports are smaller than the ports in the head that the mismatch won't hurt. Vice versa I heard was bad. Headers, Headers, Headers! With your combo Headers would be a bigger gain than porting. But, every small bit of horsepower is how you make big horsepower so go for the porting. If you have to pay for the porting than headers are going to be a much higher Hp/dollar value. Headers not only reduce back pressure, they actually scavenge your cylinders. They reduce pumping losses which are caused by the pistons forcing the spent gases out of the cylinder. Pumping losses directly reduce torque.

The Olds head can gain about 80% of its total potential flow by matching ports on intake and exhaust side (yes grind out those headers), removing A.I.R. hump in the exhaust port, clean up of the bowl area behind the valve seat, and tear dropping, or at least narrowing the valve guides. The metal around the valve guide is round from the factory, and you grind it so that it is shaped more like a teardrop, with the skinny end pointing away from the valve.

Let's once again put to rest this misnomer which a prominent Olds parts house and rebuilder continues to perpetuate. EGR (exhaust gas recirculation) is a pollution control system which lives in the intake manifold. The issue with the heads is the incorporation of "bumps" in the exhaust ports to allow the accommodation of the air injection system (A.I.R. - air injector reactor, aka a smog pump). A.I.R. was used on 66-67 California cars only, then on later cars, though I'm not quite sure of the exact years. Most Olds motors do not7 have A.I.R., however the bumps are cast into all Olds heads, causing an exhaust restriction. Grinding out these bumps is an easy way to improve exhaust flow. Just please don't refer to them as "EGR bumps".

The intake runner of the head should stay rough to help the fuel atomization. Smoothing the surfaces til they are smooth and shiny will cause fuel puddling and reduce atomization.

When looking at an Olds head exhaust port you will notice the A.I.R. hump on the roof of the port just inside (header side). This hump when ground out so that its flush with the surrounding area will net a gain of approx 30% on the exhaust flow. Also blend it into the roof of the port. There is also a kind of depression next to the A.I.R. boss (it wasn't used for EGR, though it may unintentionally have had that effect) that you will need to blend in to the rest of the port roof as well.

An Olds motor definitely needs exhaust work prioritized over intake work. In addition, the exhaust ports should be polished smooth, while the intakes should be rough to promote turbulence to keep the fuel droplets in suspension in the air flow. Note that in the latest issue of National Dragster, Warren Johnson indicated that ideal exhaust port flow should only be about 70%-80% of intake port flow as measured on a flow bench.

To port match, you scribe the outline of the port from the gasket on the surface of both the head and the manifold, and then grind the entire port up and out to that point.

Just short of all out porting is to have the heads bowl ported to a distance of about 1" just down from the valve seat and blended into the port runners the basic idea is to try to get the bowl area to about 75% of the valve diameter.

This one mod alone will increase power better than any dual pattern camshaft would (when you attribute the increase to the dual pattern and not the camshaft profile). Larger valves can be cut into any head. Unless your cam is really wild, however, and you're turning 6000+rpm, just removing the A.I.R. bumps, tear dropping the valve guides and smoothing out the transition from the valve seat to the port will be sufficient. No sense in trying to increase port volume or such.

Make sure that the shop you take the heads to will actually do a three angle valve job.

Have the intake and exhaust valves back cut on the back side of the valve (called back cutting the valve). Also try to have the back sides of the valves polished or smoothed out.

Have the center exhaust port divider welded up and then milled flush with the rest of the exhaust gasket seating surface.

Needless to say, you should also completely wash out the head after porting it; metal particles and shavings will be everywhere after your porting job!

Any further porting should be left to someone with more experience, as flow can be just as easily reduced as increased.

Cut the head for the larger valves including the sides of the chambers to unshroud the valves (brought chamber size from 64cc to 67cc). Milled head surface to decrease chamber size (went from 67cc to 62cc). Polished the exhaust ports and removed the AIR bumps. Tear dropped the valve guides and hand blended the cuts from installing the larger valves. I also installed hardened seats though I have seen many Olds heads that didn't have them and had many miles on unleaded with no valve recession (iron Olds used is so hard it acts like a hardened seat, will also take twice as long to port). There are also other things you can do like fill the exhaust crossover (not recommended for daily driver, especially if it gets cold in your location) and cutting back the exhaust divider. What you want from your motor will dictate how much work you put in the heads. BTW I ran the stock rockers with a radical cam so as long as you set the heads up right you can save some money there.

Mondello offers an entire kit (~$70), with the cartridge rolls and the carbide burrs you would need. You can pick up seperate pieces if you run out, but the whole package will end up costing more if purchased seperately. Go with the Mondello kit, unless you find a good cheaper source for everything.

The carbide burrs are like rotary files on the end of a shank, and you use them to remove material; they come in a few different shapes, such as round and almond-shaped, as well as triangular. I found myself using the round one most often (wore it out, in fact, on one set of heads).

The cartridge rolls are just strips of sandpaper rolled-up like a jelly roll, which screw on to the end of a shank; as you use up the abrasive, that bit of the roll breaks loose, revealing new abrasive underneath (I didn't know this, and got concerned when bits of these things started flying off the tool at 22,000rpm!) They don't really remove much material, and you'd go through a lot of them if you tried to port a head with them alone. You use them for final polishing and blending, and perhaps to even out the surface.

[ Thanks to Chris Witt, Tom Lentz, Robert Whitaker, Mark Prince, Chris Urban, Cliff Feiler, Danny, Bob Barry, Tony, Joe Padavano, others, Dan Mann, Mike Bloomer for this information ]

Milling

When milling the heads, you will need to have either your intake port sides milled the same amount, or have the intake side of the heads milled. Most better shops will mill the intake sides when they mill the heads so everything will match back up.

Apparantly we Oldsheads (poor pun) have been overtaught by ch*vy teachers and tech articles. blowtie decks are not at 90 deg angles to their intake surfaces. Olds heads, on the other hand, are "perfectly" designed at 90 Degrees. Therefore, if you chop, say two inches (!!!) off the bottom of the head, the intake planes will still be parallel. (Of course, the rocker arms would be in the oil pan by that point, but...)

The best thing to do with milling (piston clearance aside) is to port match the heads to the intake (or vice-versa) ~after~ the milling is done. If you match 'em up before hand, you'll be off a bit. Charley Buehner

Actually the most desired way to resurface any cylinder head, or engine block is by using a 'Rotary Broach' machine. This will ensure that you have a flat surface. A belt sander will smooth the surface but will not create a flat surface. Steve Reed

Also be sure to check out how this milling will affect the valvetrain, it might not affect it but it doesn't hurt to find out before trouble ruins the fun of getting that bad-boy 455 back together and screamin! Ken Snyder I had my "J" heads milled .060 " about a year ago. In order to get everything straight you need to mill the intake as well. My Dad did the millwork, we took some off the head sides of the intake. To be perfectly accurate you also need to take some off of the bottom of the intake, but with the squishy rubber gaskets you can probably get away without it. Vince Knight Knightvd@aol.com Olds heads are 90 degree surfaces, so head intake side cut == head to block side cut. Don't let the mechanics start multiplying by some Chevy number to get the "right cut" for the head intake side cut. You CAN also cut the block rail seal surface of the intake, but you'd be better off to just eliminate the rubber or cork strip and seal w/ a bead of silly-cone. Should you choose to cut, the amount of said cut would be sqrt(2) or 1.414 times the cut off the intake surfaces. I think. either that or 1/1.414= .707- the machinist should know. Chris Witt I finally sat down & cleared up the confusion of this one. Assuming that the intake ports were *perfectly* matched before you started, so that we can forget for now the head gasket diffs, etc. Cut the intake's intake [head port] surface the same amount as the heads were cut. Cut the intake's front & rear rails [horizontal surface where meets block] an amount equal to sqrt(2) * head cut, a.k.a. intake bottom cut = 1.414 * head cut. To be even better, do as Mondello says, port-match the intake to the head. Then cut intake bottom = 1.414 * intake's port cut. The fact is that it's a simple 1-1-root2 right triangle. Chris Witt

Octane Boosters

A note for people that use leaded aditives for their fuel.

It will destroy the useful aspects of the catalytic converter.

When leaded additives were commonplace in the refineries, the people that handled the lead material did so with extreme caution, and took extensive precautions.

It is considered a poison with extreme toxicity.

If you use this material, wear thick rubber gloves, good eye protection and a respirator face masks at a very minimum. Do not come into physical contact at all.

Remember when gasoline was 'red.' The red was an aniline dye added for anti-knock (relative octaine boost) purposes. It too is harmful to C.C.s.

I don't have a problem with my 10.25:1 455 in the Cutlass (back when I mixed 92 unleaded with 89 leaded), and even now I don't have a problem running my '69 Toro's 10.25:1 455 on 92 or 93 octane unleaded.

I did have a problem with part-throttle pinging, and even backing the timing way down was not enough to cure it. I bought an adjustable Crane vacuum advance unit, followed the tuning advice (it also includes springs and a vacuum advance limiter), and have no pinging on even the hottest of days lugging it up a hill at part throttle, with the initial advance set at the factory 8' BTDC. It seemed that the problem was the excessive vacuum advance under part-throttle load; with the Crane kit, I could tune the spark curve to reduce the advance under those conditions, but keep it at just under pinging in all other places. Highly recommended.

I have mine set at the factory 12' initial advance with 34'-36' total on my 455 with 10.5:1. I don't have any pinging or knocking at any rpm or load. I am using straight pump unleaded Chevron Super Supreme 94 Octane gas. It is the only gas station in Canada that has a 94 Octane fuel. If I use a 92 or 91 Octane then I do get pinging. I have all the stock components under the hood (for now). I did purchase a MSD Adjustabe timing control (I have yet to install it) to use so that when I do travel to areas that don't have 94 Octane gas, then I can just turn the little dial and retard the timing by up to 15'. I have seen it work and would also highly recommended them (ie. either the Crane or MSD system).

Most of the time I go out to the local airport, purchase about 10 gallons of av-gas, and run a 2:20 (2gal av-gas:20 gal super unleaded), and my 10.25:1 350 runs fine at just about any timing setting.

VP Racing Fuel says that octane does not matter as much as the blend of the fuel does. It is all a matter of how well an engine can burn the fuel. They sell a leaded and un-leaded racing gas for stock engines, they sell gas for NHRA Pro Stock racers, and everthing in between. If you tried to run their highest grade stuff in your street car, it most likely would not run at all. Your stock engine does not make enough compression.

I used to run a 50-50 mix of unleaded premium and VP Red (the lowest grade of leaded) in my Fairlane with great results. I have also ran brand X racing fuel with the same mix ratio in my Olds with great results. I thought I had Sunoco 260 in the tank again, just like the old days. I have a friend that runs 3-4 gallons of racing gas with a tank full of premium in his GTOs. He reports smoother running and driveability. I would seek out a racing fuel supplier and shy away from aviation fuel. VP is headquartered in Dallas, Texas and has bulk plants all over the U.S.

When I tried Lead Supreme 130 I found that I could put my timing almost anywhere I wanted it. LS 130 uses the same additives the oil companies used in the good old days. This includes tetraethyl and toulene. One ounce per gal. will raise 93 octane gas to 95 octane. You can custom blend to your own octane needs.

To raise the octane 1 point (of course I am speaking of R+M/2 method) from 93 to 94 one gallon of LS 130 will yield 214 gals of treated gas. This will really only protect valves and CRs of 9.5:1. To raise octane 2 points add 1 ounce per gallon this will make 129 gals. to get 4 points add 4 ounces per gallon this will make 32.5 gals. For racin' 1 gallon of LS 130 to 9 gals of super unleaded will raise octane 8 points.

One gallon of LS 130 is about $18.00 less S/H.

Product Comments

104+ Good stuff. Car pings a little 90% effective.

Bartyls Lead additive and Octane booster. 80% effective

Snap Octane booster. Save your money.

Trick Octane booster. Haven't tried it yet.

Stp Octane booster. 75% effective.

[ Thanks to Bob Barry, Nick DiGiovanni, Stephen Hoover, Cliff Feiler, Dave Wyatt, Danny, Chris Sparks for this information

Oversize Valves

Joe Mondello does not advise the use oversize exhaust valves when hardened exhaust valve seats are being installed in a head. The use of 1.71" exhaust valves w/hardened seat inserts and a 2.07" intake can result in intrusion of the hardened seat insert into the intake seat area. I asked him about this because I had already done exactly what was not recommended. After about 20,000 miles, I have had no problems, but a very small portion of my intake seat is very close to the insert. I think the risk is worth it, since I wanted it all (big valves and the durability of hardened seats).

[ Thanks to Scott Mullen for this information ]

Removal and Replacement

Remove the air cleaner, distributor cap and wires, and disconnect and mark all vacuum hoses and wires that either can't stay on the intake or lead off the motor. BTW make sure you disconnect the battery before you begin. Take a good look at where everything goes and draw sketches if that helps you. Another good idea is to use ziplock baggies to put the bolts in and tape them to the part they held in.

Drain the radiator, then pull the lower radiator hose to let the rest of the fluid drain. Remove the heater hose from the back of the intake. Remove the upper radiator hose and loosen the clamps on the bypass hose from the thermostat housing to the water pump. You can pull off the t-stat housing, don't have to but it makes things easier.

If your car has A/C, you'll have to unbolt the compressor from the brackets and set it out of the way. Use a coat hanger to keep it from flopping so you don't damage the hoses. Remove the A/C brackets.

Remove the wires to the alternator and pull it off along with the upper bracket. I think you can leave the P/S pump attached but it may be easier to unbolt it and let it rest down, out of your way. On some cars it overlaps the exhaust manifold which will get in your way.

Mark the dist housing where the rotor is pointing. Then make a note of which direction the vacuum advance points so you can put it back the way it was. I don't usually pull the dist, but some find it easier to get the intake out this way.

Unbolt the intake and remove it. Sometimes the valve cover lip will interfere and you have to remove at least one to get the intake off.

Remove valve covers. Unbolt exhaust manifolds. Since you're replacing the heads, you shouldn't have to worry about broken bolts.

Unbolt the head bolts and remove the heads. I intentionally left out removing the rocker arms since they can be left on the head and help push the head off the block. Be careful when prying the head or the intake off if they're stuck so you don't scar the mating surface. When you put it back together bolt the head down and then install the rockers but make sure you tighten the 2 rocker down even so you don't break one of the pivots. Also, when you remove the heads some coolant will go into the cyls. Have some paper towels ready to dry everything out. As far as torque pattern, always (on everything) start in the middle and work in a circular pattern towards the ends. Some thing like this:

8 4 1 5 9

7 3 2 6 10

Works on intakes, heads, valve covers, etc. As far as torque, I think it's 80, but check with an Olds chassis manual.

Make sure you scrape all gasket surfaces clean without dropping anything in the engine. If you have an air comp, use a spray nozzle to make sure all trash is out of the cylinders. I like to use brake cleaner to clean the mating surfaces and run a honing stone over them. The brake cleaner is nice since it dries fast and doesn't leave a residue. Clean your head bolts and wire wheel/brush the threads so you get an accurate torque. Dip them in oil when you install them for the same reason.

The rest of reassembly is the opposite of what I've already said.

[ Thanks to Mike Bloomer for this information. ]

Rocker Arm Ratio

Subject: Re: 1.7 ratio rockers I do believe you'd mess up rocker geometry. The tip of the rocker would hit the valve stem way over on the edge, instead of just off center. Maybe even get caught on the edge and bend valves. __________ While you're correct that the different ratio will change the rocker geometry, and thus require adjustable rockers, you don't need to change the pivot-to-valve stem dimension to get a different ratio. You can accomplish the same thing by shortening the pivot-to-pushrod dimension. Obviously, this may require enlarging the pushrod holes in the head, but it solves the valve stem problem. Joe Padavano

Springs

My machinist and the Summit catalog seem to agree that the 302 Ford has the same springs as the usual Olds.

[ Thanks to Chris Witt for this information ]

Stainless Steel Valves

From what I have read the cause of seat recesson is that when the exaust valve closes a few molecules of the seat weld themselvs to the valve. When the valve opens these are ripped off the seat and go out with the exaust. Leaded gas helped to prevent this by forming a cushon and lubricating the seat and valve mating area with molecules of lead. S/S valves may help some but I don't think they would prevent it.

Stainless steels have thermal conductivities along the lines of 15 W/m k, versus carbon steels that are aound 60 W/m k. This means that the stainless valve will not conduct nearly as much heat to the valve seat when they are in intimate contact as the carbon steel valve. I know that the exhaust gases will still be rushing by the seat at the same temperatures, but they will not be slamming against the seat, in a way providing a weak sister of a force weld. The continual contact at much elevated temperatures will result in earlier wear. How much, I don't know. Always ask a guy with experience for that kind of info.

The conductivity is much lower in the S/S valve, it will take on less heat than the carbon steel. It will also not give it up as readily. the decreased thermal conductivity causes the stainless steel valve to retain more energy in the form of heat at the stem. This is because the rate of heat transfer to the valve guide is lower. Basically, the S/S valve has higher heat resistant properties and is more resistant to mechanical stresses and strains than the carbon steel valve.

Truck engines (I mean real trucks, not pickups) have used hardned seats for years. Not even leaded fuel will save the cast iron seats when the exaust temp gets high. A truck pulling a heavy load up a steep grade is very hard on seats, as is a motorhome that catches a lot of wind and is heavy too. This is because the throttle is wide open at a low rpm for a long period of time creating very high exaust gas temp. Sometimes the manifolds will turn cherry red. It doesn't take many miles under these conditons to completely destroy a seat.

I have seen very few high performance engines have seat problems even when using older heads. I think that this is because most ot these engines are run with a richer mixture which helps keep the exhaust gas temperature down and they are not run under lugging conditons. Of course they are usually driven less miles so that helps too.

If I am building heads for car that will be hot rodded I offer to put in hard seats if they want. If the vehicle is to get a lot of highway miles and doesn't have the factory induction hardened seats I recomend them. If it is to pull a trailer I insist on them.

[ Thanks to Walter, Paul Brillhart for this information ]

Heads 1995 - Present

Identification

All aluminum, with 4.0 appearing near the top edge of the head.

ID/ Casting

Code Year(s) CID CCs Number Notes

1647501 LH;

1647504 RH;