| ||||

| ||||

| ||||

| ||||

| ||||

| ||||

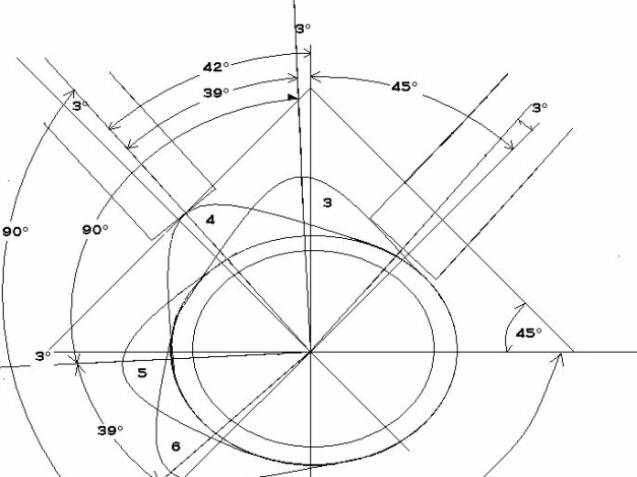

2. Some may argue, or disagree, but this is my way. I`ve talked in length to people that actually understand the principle. It is an accurate way of determining angle. I`ll try and keep the pics in order of 39 vs.45. Make sure your square is square, your straight edge is straight. Using a lifter as a guide won`t work, it`s just too sloppy.

39 block with straight edge snugly laid flat against lifter bore, square laid on block. Square touching bottom, gap INCREASES with rise.

3. On the 45 degree block, the square stays parallel to straight edge.

| ||||

| ||||

If you have a good tip, share it with all of us. It will be appreciated.

12

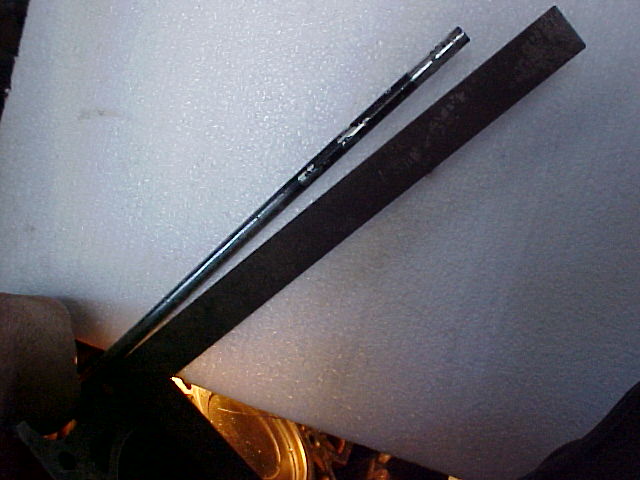

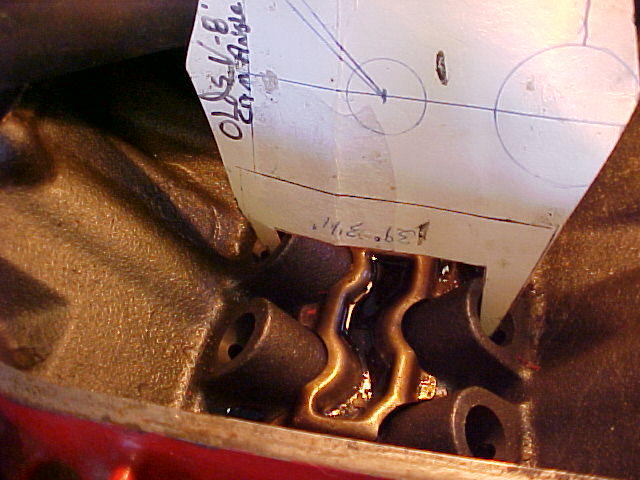

6. Then I made a crude measurement tool. By understanding the design, it makes sense, that since the lifters are laying on different planes, that there has to be a measurable difference. No surprise, there is. I`ve checked several blocks with this tool, 330`s 400`s 425`s 455`s. It`s never lied

The 45 blocks have a wider measurement than the 39`s (lifter bore diameter MUST be taken in to consideration)

39 degree block with 39 degree measurment measurement.

5. The protractor sits flat against the block deck on the 45 degree.

| ||||

7. This is the 45 degree block with 39 degree measurement.

The first thing you want to do is stop reading articles and posts on this subject. 99.9% sure you`ve got a 39 block. I`ll get you some pics on how to check this later, just can`t do it right now. There`s only a 3 degree difference per side. The 39 and 45 degree angle is taken from the true centerline. Run an imaginary line up from the crank thru the cam, since the head surfaces of the block are at a 45 degree angle from the centerline, a 45 blocks lifter bores will be at a 90 degree angle to the deck of the block, or parallel to the cylinder bore. Now I`ve seen and measured blocks that are slightly off both + and -, I chalk this up to mass production.

1. Check this out, it`ll give you an idea what I`m speaking of.

4. Using a protractor, set at 90 degrees, set the leg of the protractor down the lifter bore, with the leg seated flat against the lifter bore, note the angle of the protractor in relation to the block deck.

Notice the gap on the bottom edge of the protractor, it's a 39 degree block.

5. This is the 39 degree block with 45 degree measurement.

5. This is the 45 degree block with 45 degree measurement.

I hope this makes your task a little easier. Don`t believe all that B.S. about drill spots, lifter size, pixy dust and magic potions. Mike Dulak